Chemical Recycling: underwhelming and oversold

Not living up to the hype

In a zero waste society, we want to use our resources in the best way possible. For the materials and products where waste prevention and reuse is not yet a reality – be it technically, legislatively, or financially – we turn to recycling. However, things can get a bit complicated here. Different recycling technologies can have very different impacts on the environment and climate.

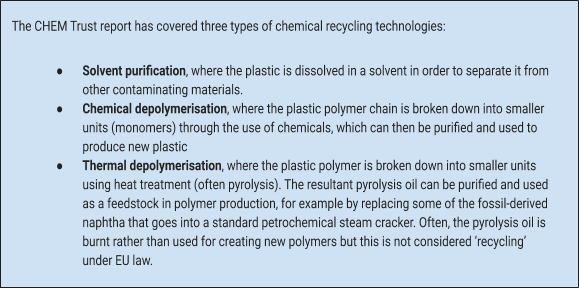

Recently, heavy attention has been paid to so-called ‘chemical recycling’. This term currently refers to the conversion of plastic waste into its basic building blocks, often in the form of oil, which can then be used as feedstock to create new plastics. These technologies include pyrolysis (breaking down plastic with high energy and little to no oxygen) and gasification, which have been around for many years without successfully managing to scale up their plastic-to-plastic processes. Yet, they are often claimed to be on the cusp of revolutionising the recycling of plastics.

In reality, ‘chemical recycling’ technologies require large amounts of energy compared to conventional recycling. They also need clean, homogenous waste streams to produce good quality outputs – something that risks competition with more sustainable recycling technologies like mechanical recycling when it comes to waste feedstock.

New report bares it all

While the limitations and risks of ‘chemical recycling’ have become increasingly clear for many environmental organisations, the organisation CHEM Trust and the consultancy Eunomia have recently detailed the lay of the land by reviewing the performance and impacts of different ‘chemical recycling’ technologies in their report Chemical Recycling: State of Play. The report also highlights concerns over hazardous chemicals in these processes. It turns out that we really don’t know enough, and while some of the technologies might bear promise as a complement to conventional recycling, we must be careful not to “‘’lock-in’ increased environmental impacts over the long term in a similar way in which the shift towards waste-to-energy has done so in countries that have invested heavily in incinerators”.

As described by Dr Michael Warhurst, Executive Director of CHEM Trust:

“In the context of a clean and safe circular economy, as advocated by CHEM Trust, it appears that chemical recycling is being oversold […] The end result may still be contaminated with hazardous chemicals, and the economic viability of many of these technologies is in doubt.”

Are we there yet?

In assessing the three types of technologies, the report investigated their technical and commercial maturity. While the report covers more detail, simply put, solvent purification was found to have the most promise in very niche applications – such as electrical consumer goods packaging or insulation panels with legacy fire retardants that cannot be mechanically recycled. However, the technology essentially degrades the material, which does not allow for infinite recycling, and competitiveness with mechanical recycling was not considered likely due to the high energy demands.

Chemical depolymerisation was claimed to produce purer outputs and hold promise for PET/polyester. However, high yields appeared to only be possible when using clean and homogenous waste streams, and such fractions can already be recycled mechanically. As an example, chemical depolymerisation for PET bottles was considered unlikely to compete with mechanical recycling, particularly when they are part of a deposit return fund system (DRS).

While thermal depolymerisation (such as pyrolysis) as a way of producing feedstock to make new plastics has yet to be proven commercially, it has been a more established way to produce fuels. To keep in mind: as plastic is a fossil-derived material, turning plastic into fuel releases the fossil carbon embedded in the material into the atmosphere! It turns out that using pyrolysis of plastic waste to instead produce feedstock for new plastic also comes with material and carbon losses compared to conventional recycling. The resulting pyrolysis oil either needs to be purified in several steps or be mixed with virgin fossil fuels before going through the cracker to produce materials useful for plastic production; generating wastes that are likely to be hazardous. While the claim that dirty and mixed plastic waste can be treated with thermal depolymerisation is theoretically correct, this leads to low yields and outputs that are likely to be too contaminated to meet the cracker requirements. Therefore, any advanced sorting and washing of plastic waste needed for mechanical recycling will probably also be needed for pyrolysis.

With the biggest selling point of chemical recycling being the ability to treat all types of plastic, this trade-off is likely to reduce incentives to further explore thermal depolymerisation as a sustainable plastic recovery method. However, the report acknowledges the potential application for specific waste streams which are not attractive to mechanical recyclers, like mixed but clean polyolefins such as films.

Can we afford the environmental impacts?

Sure, recycling plastics is good. But getting rid of the plastic waste heaps through methods which may pollute our air and environment is not great. Our atmosphere is in no need of the extra GHG emissions which could come from plastic waste being diverted from mechanical recycling towards more energy-intensive technologies. And even for the technologies that seem to have the potential for specific waste streams, this should not obstruct efforts to reduce or prevent this type of waste.

If you believe the industry, chemical recycling has the potential to separate out hazardous chemicals and substances so that the recycled plastic is even safe enough to be used in contact with food. However, the CHEM Trust and Eunomia study found that there is not enough information about the nature, quantity, and toxicity of the solvents and chemicals used, as well as the fate of the waste and by-products formed during the process itself. In reviewing some existing life cycle assessments, the authors point to energy use as the most important aspect to consider in terms of environmental impact, and highlight a lack of consistency and transparency in assessing the yields of the various technologies.

One important observation was that “even when compared with a relatively poorly performing mechanical recycling scenario, current pyrolysis oil to monomer processes appear to be too energy intensive to compete”.

An overriding finding of the report is that there is a need for greater transparency and evidence on the performance and viability of these technologies, especially considering the many unverified claims about their sustainability. It is still unknown whether this due to a lack of knowledge or a lack of willingness to share unfavourable information. Until then, caution is key, and “investments should be reserved for those organisations that freely engage to improve the understanding around these missing elements”.

As it appears unlikely that chemical recycling and recovery can perform favourably from an environmental perspective, the EU should take a precautionary approach and clarify their position on these technologies as secondary to mechanical recycling. Their use should be particularly restricted in cases where the carbon footprint from their processes are higher than the production of virgin plastic. If not, we’re just exchanging the plastic waste issue for a climate change problem. The EU taxonomy would be an important opportunity to encourage investments in, and provide support to, the manufacturing of plastics from secondary materials from mechanical recycling, rather than from high-energy technologies. Several recent initiatives – including the taxonomy, the Chemicals Strategy for Sustainability and the new Circular Economy Action Plan – make reference to chemical recycling and its environmental impact. The European Commission should therefore support the development of more independent, transparent, and comprehensive assessments of environmental and climate impacts of chemical recycling – based on primary data sources – before further developing legislative frameworks incentivising these technologies.

Want to know more about the state of chemical recycling in Europe?

- Read the Executive Summary of CHEM Trust and Eunomia’s report “State of Play: Chemical Recycling” or the full report.

- Explore our ten concerns with existing chemical recycling life cycle assessments

- Discover our joint statement with the Rethink Plastic alliance, and notably, ECOS, EEB, and HCWH, which outlines key steps for effective legislation of chemical recycling in the EU.

- Dig into the topic with our study: El Dorado of Chemical Recycling, State of play and policy challenges.

- Read Zoe Casey blog on why chemical recycling won’t solve the plastic crisis.